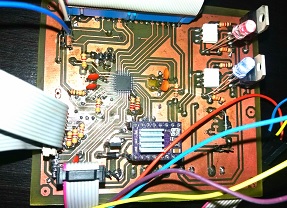

Development of custom electronic boards with CNC Router.

Your project should incorporate:

The clean water dispenser is a device designed to provide safe, filtered water for home consumption. Use electronic sensors to monitor water fill and quality, ensuring that only clean water free of impurities is dispensed.

Electronic Level Sensor: Monitors the water level in the tank and controls automatic filling using a solenoid valve. This ensures that the tank will always have enough water available without overflows.

Prefilter: The water first passes through a prefilter that removes large particles and sediment.

Controls the flow of water, allowing passage only when the quality sensors approve the water.

Automatic Tank Filling:When the level sensor detects that the water in the tank is below a certain point, activate the solenoid valve to fill the tank. The solenoid valve closes automatically once the optimal level is reached.

As water enters the system, TDS and turbidity sensors continuously analyze water quality. If the water does not meet quality standards, the solenoid valve closes and an alert is issued to the user.

Water is only allowed to pass through the filtration system and to the points of use (faucet, dispenser, etc.) when sensors confirm that the water is clean. The pre-filter ensures that large impurities are removed before the water reaches the consumers.

OSB.

Glass.

Flexible hose.

Tap.

Teflon tape.

Filter.

XIAO ESP32-C3

Solenoid Valve.

TDS.

Turbidity.

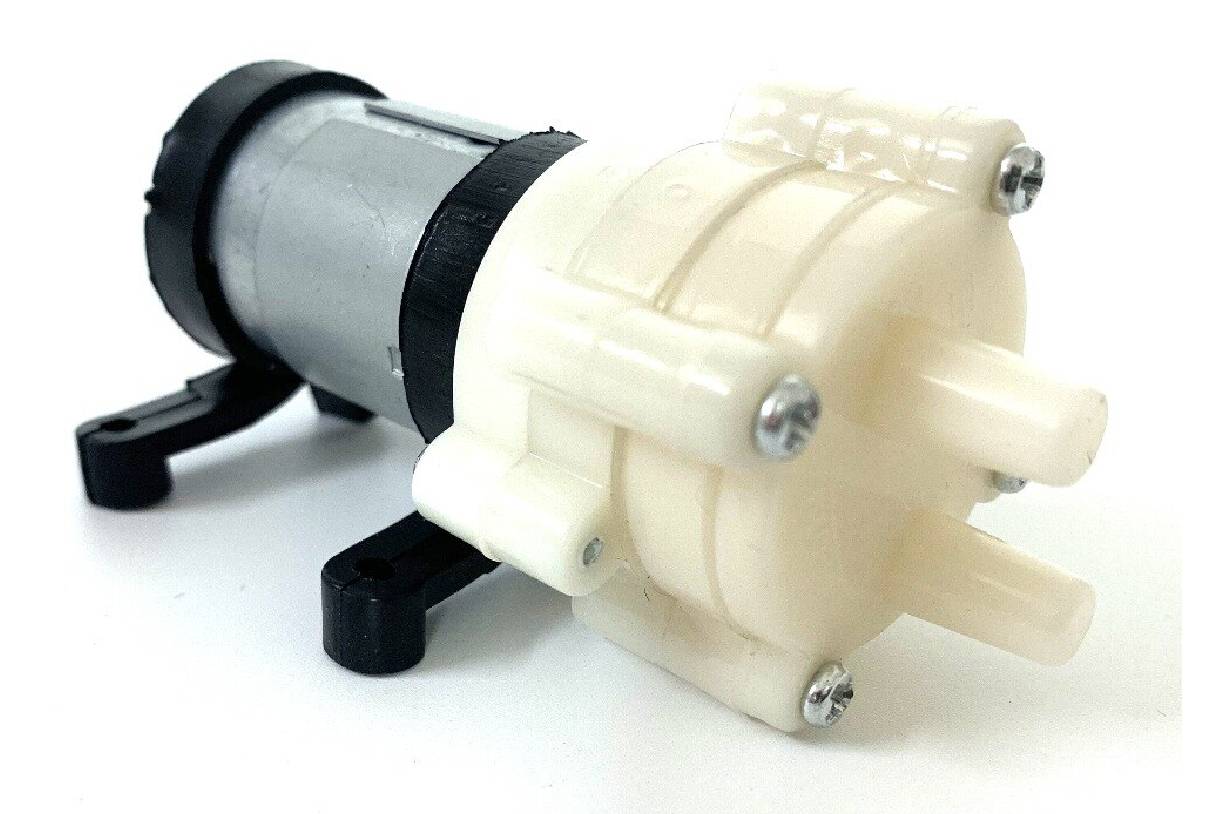

Peristaltic Pump

Level Sensor.

Touch Sensor.

RGB Led.

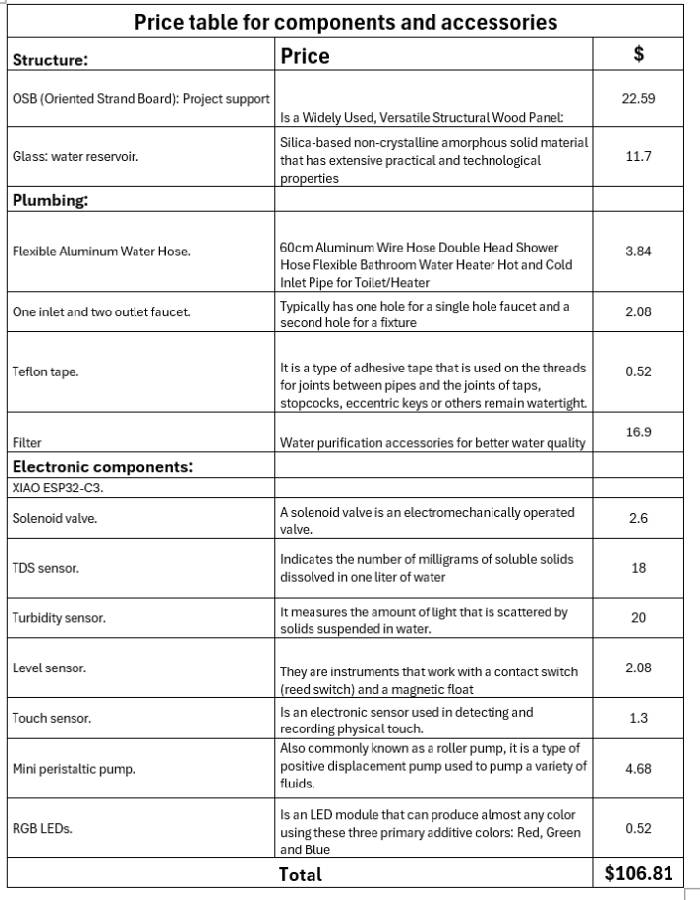

But we can place the prices of the materials and the approximate price up to this level of the project.

I am currently going to make the price of my project with an estimate taking into account the different processes it has that make it unique, in my case they are: 300 dollars

The development of my project involves a series of integrated processes to achieve a unique and functional product. We begin with 2D and 3D design using Kicad software for electronics design. Electronic production is carried out with a homemade CNC machine, where the electronics necessary for the XIAO ESP32-C3 and the relay modules are manufactured.

For the structure, we employ computer-controlled machining processes using OSB material. As for the output devices, the control of a mini peristaltic pump is done through a relay module, and a solenoid valve is activated based on the water parameters, such as TDS, NTU and level, read by the sensors. These sensors are essential input devices for the operation of the system.

The integration of networks and communications allows sensor values to be displayed on a local dashboard, communicated via WiFi and accessible from cell phones and computers. This is complemented by embedded programming to manage the devices' firmware. Additionally, the project includes the molding and casting of a Fablab logo, which acts as an LED indicator.

In summary, this project combines a wide variety of processes that not only strengthen its functionality and uniqueness, but have also allowed me to develop and consolidate my skills and knowledge. Additionally, it demonstrates how the integration of multiple processes can add significant value to any project.